Return to News

FOSTERING THE NEXT GENERATION OF MASONS

It’s no secret that the construction industry has been plagued in recent years with a shortage of skilled labor. According to the U.S. Bureau of Labor and Statistics, the 12-month job opening average in the construction industry is currently at a post-recession high and trending upwards. Trowel in hand, Echelon Masonry and parent company, Oldcastle APG, are working closely with various organizations throughout the country to proactively address this growing concern.

“Oldcastle APG has a deep commitment to fostering the next generation of masons and has been doing so for the last several years through national investments in MCAA education and regional work with SkillsUSA and various state masonry organizations,” says John Cicciarelli, National Commercial Masonry Manager, Oldcastle APG.

In addition to a national $500,000 pledge to MCAA’s The Masonry Foundation, multiple Oldcastle APG companies across the U.S. work locally to reach the younger generation and help encourage career paths in the masonry field. This is best illustrated by multiple programs in the Carolinas implemented through the North Carolina-based Echelon Masonry manufacturer, Adams, an Oldcastle company.

“Adams and Oldcastle have been phenomenal in supporting our efforts to ensure we do not lose any share of the skilled labor force,” says Ryan Shaver, Workforce Development and Training Coordinator for the North Carolina Masonry Contractors Association. “We’re already facing a shortage of masons. If we don’t become proactive now, what will we do in five years or 10 years?”

Recruitment Begins at the High School Level

One of the programs created by the NCMCA and supported by Oldcastle is a high school pre-apprenticeship program, which allows students to simultaneously earn wages and high school credits by working in the masonry industry during school breaks. Hours spent during this pre-apprenticeship period apply towards certification requirements should the students elect to continue into a full apprenticeship upon graduation from high school. This allows apprentices who participated at the high school level to earn certification more quickly.

“This masonry pre-apprenticeship program is the first statewide initiative of its kind in North Carolina and will pave the way for other trades,” says Shaver. “It’s our belief that if you start the recruiting process before they’re 18, we’ll have a better chance of retaining these kids in the industry, and we’ll be tracking that retention rate moving forward.”

Adams supports these aspiring masons by hosting and sponsoring the annual Butch Hardy Memorial Masonry “Top Trowel” Competition at its Goldsboro, NC, manufacturing facility. This year’s event held in May 2018 drew over 100 high school students who participated in three separate masonry competitions including a “lineburner” speed bricklaying contest. A total of $7,500 in cash and prizes were awarded to the various student winners.

Sponsors and winners of the Butch Hardy competition. Bottom row: Jennifer Key (3rd place), Wade Kight (4th place), Jacob Jones (5th place). Top row: Brett Hardy of Adams/Oldcastle, Barry Parton (2nd place), NCMCA Chairman Bob Gates, Maria Torres (1st place in women’s division, 2nd overall, winner of the “lineburner” competition), Cheryl Gaw of Adams/Oldcastle, Will Light (1st in men’s division and overall).

Encouraging Workmanship at Every Stage

Adams also supports masonry apprentices across the state by hosting and sponsoring the annual NCMCA Samuel A. McGee Apprentice Masonry Skills Contest, held in May 2018 at the company’s Charlotte, NC, facility. This event saw close to 40 apprentices from across the state compete on the quality of their workmanship. Winners received prize packages that included valuable tools of the masonry trade.

Jamison “JK” Huntley defended his 2017 NCMCA masonry championship by repeating in 2018, taking home first place in a field of 38 contestants from nine NCMCA member companies. Huntley’s prize included $1,000 and a wheelbarrow full of tools. He will also represent the state of North Carolina at the MCAA International Skills Challenge in January 2019 in Las Vegas (photo by Carl Moser).

NCMCA and Adams will partner again in July for a masonry instructor training day where topics will include apprenticeships, adherence to OSHA’s new Silica Rule and various curriculum topics from the National Center for Construction Education and Research (NCCER). “Students will only be as strong as their instructors,” explains Shaver.

Adams also joins many Oldcastle companies across the nation in supporting masonry workforce development through SkillsUSA educational programs and events through volunteerism, funding and materials donations of block, brick and mortar for training and contests.

“If we don’t have people to lay masonry, our industry will become obsolete,” says Patrick Jones, Masonry Sales Manager at Adams, regarding the company’s commitment to workforce development. “Mason contractors are our teammates. This industry is a tight-knit family, so labor development has been a team effort. We also have an important message for high school students who aren’t cut out for college life. Secondary education is so expensive today, so why not start earning now instead of creating debt.”

Synergy with the Design Community

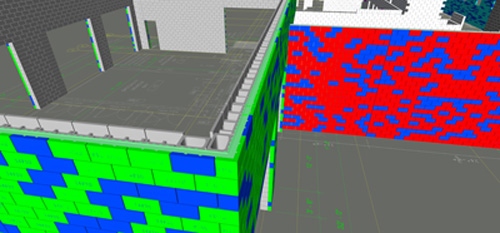

Another way Oldcastle companies support the mason contractor industry is through endorsement of the CAD BLOX service bureau. Echelon Masonry currently has the largest masonry BIM library in the industry offering support for both design and construction. CAD BLOX uses the Echelon BIM library to convert architectural designs into modeling for the mason contractor that helps facilitate proper ordering, scheduling, staging and laying of the masonry.

“The end result is reduced materials waste and reduced labor hours to help mason contractors improve workflow and better manage available resources,” says CAD BLOX developer, Tom Cuneio.

CAD BLOX services are automatically supplied with every InsulTech System™ order nationwide. CAD BLOX renderings and pattern instructions help masons efficiently order and install this innovate insulated masonry system, which requires a modified installation method versus standard CMU.

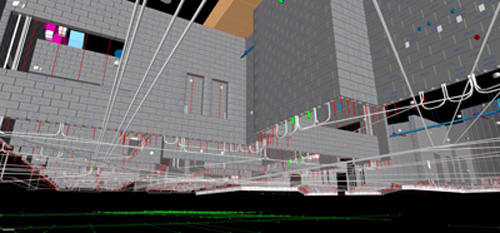

This rendering showing the view from under the slab illustrates how CAD BLOX models allow Oldcastle masonry projects to participate in 3D model coordination that reduces clashes with steel, electrical, mechanical and other trades.

In addition to offering the CAD BLOX service with their masonry orders, the Adams team has also been proactive in bringing awareness of the program to the future design community. Various Adams employees regularly work with architecture and engineering students at universities throughout the Carolinas to educate them on the CAD BLOX service. Cuneio believes this effort will help ensure efficient use of masonry labor resources in future construction projects.

“The design community also sees a benefit, especially for intricate masonry designs, in knowing that there is good support on the masonry side to make sure their designs can be built correctly, on budget, and on schedule without ordering errors or masonry delays,” he says.

Oldcastle views this integration of the design and installation processes as an important aspect of addressing the labor shortage issues facing the industry.

“Ultimately, we’re all on the same team,” says Cicciarelli. “If the construction industry is going to continue to grow, we all have to work together to both ensure a future workforce and continue to promote efficiency. Education is the key to both aspects.”

Cicciarelli notes that these types of education and support programs are being implemented by Oldcastle companies across the nation. “It’s a high priority initiative. The Adams team is definitely taking it to the next level, and others are following suit.”

- Tags:

- Company News

Return to News

Stay Connected

Get the latest news and information from Echelon by signing up to receive our monthly newsletter.